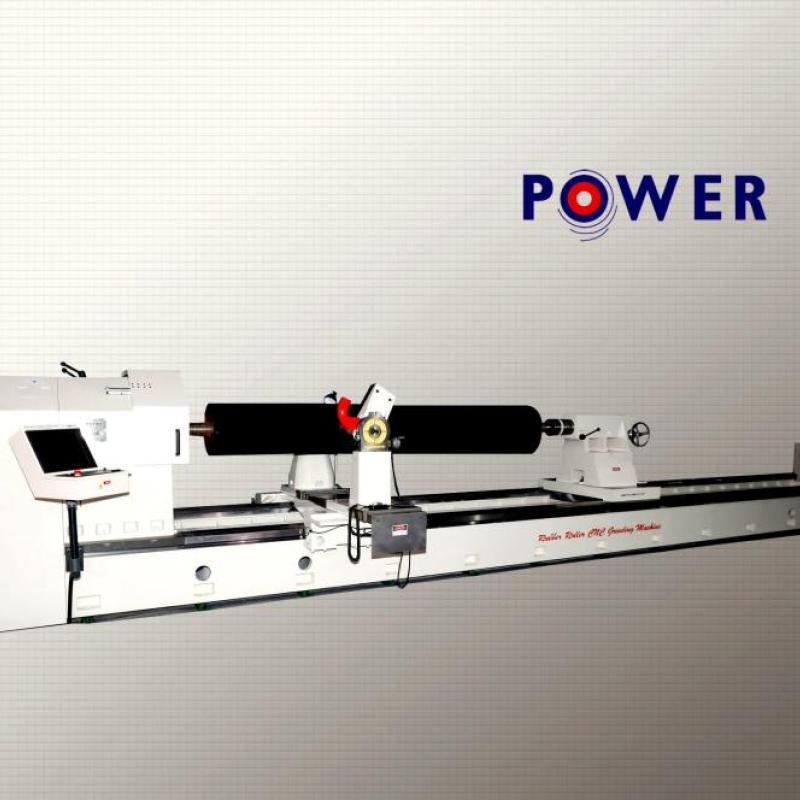

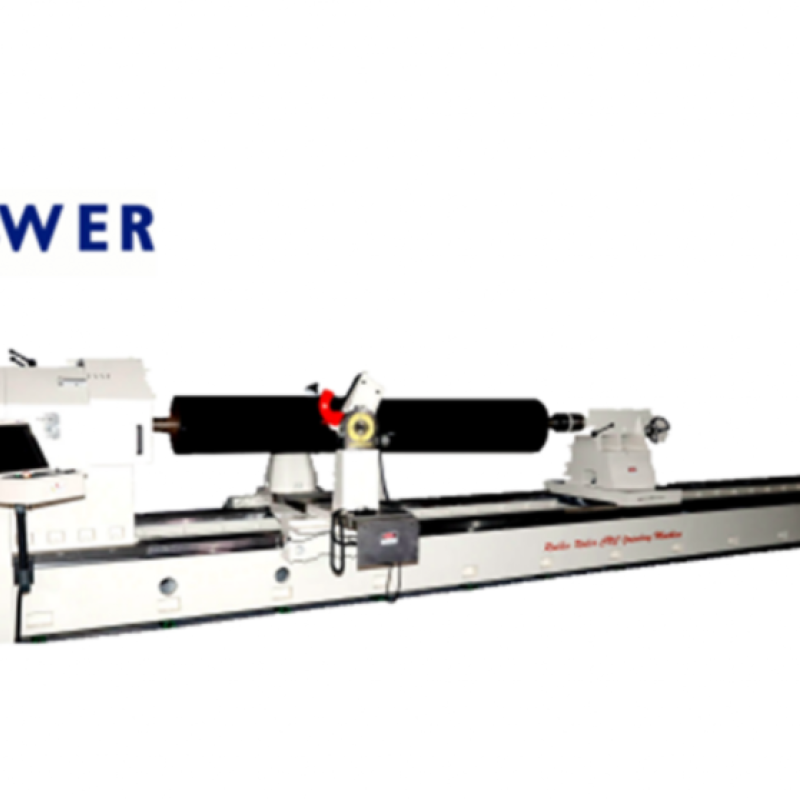

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover have to make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and remarkable formations withinside the appended drawing.1.

Contacta ahora

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contacta ahora

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contacta ahora

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contacta ahora

Product Description:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve.

Contacta ahora

Product Descriptin:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve.

Contacta ahora

Product description1. The PCM-1660 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

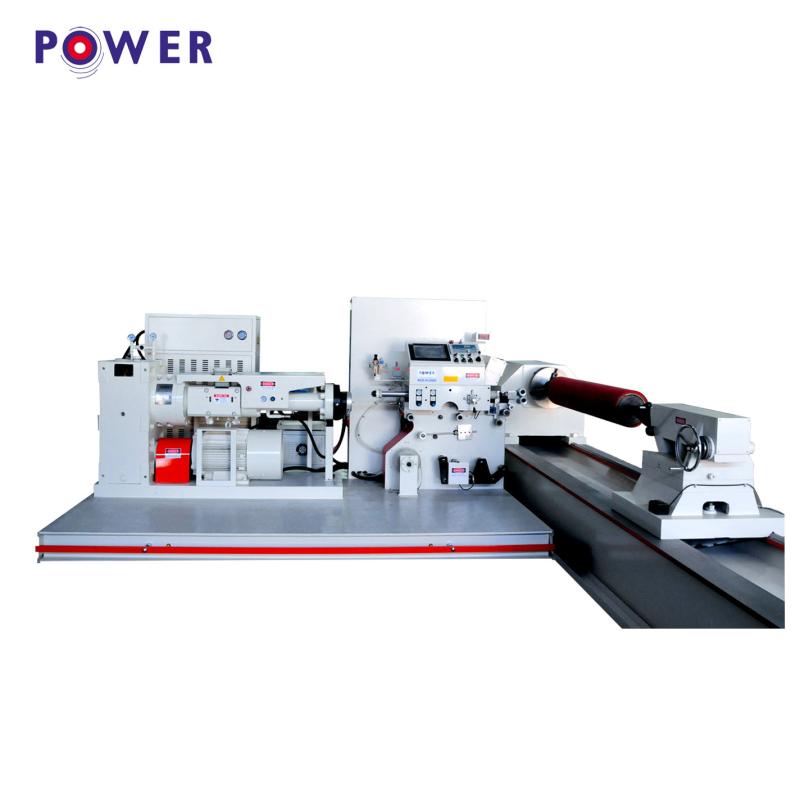

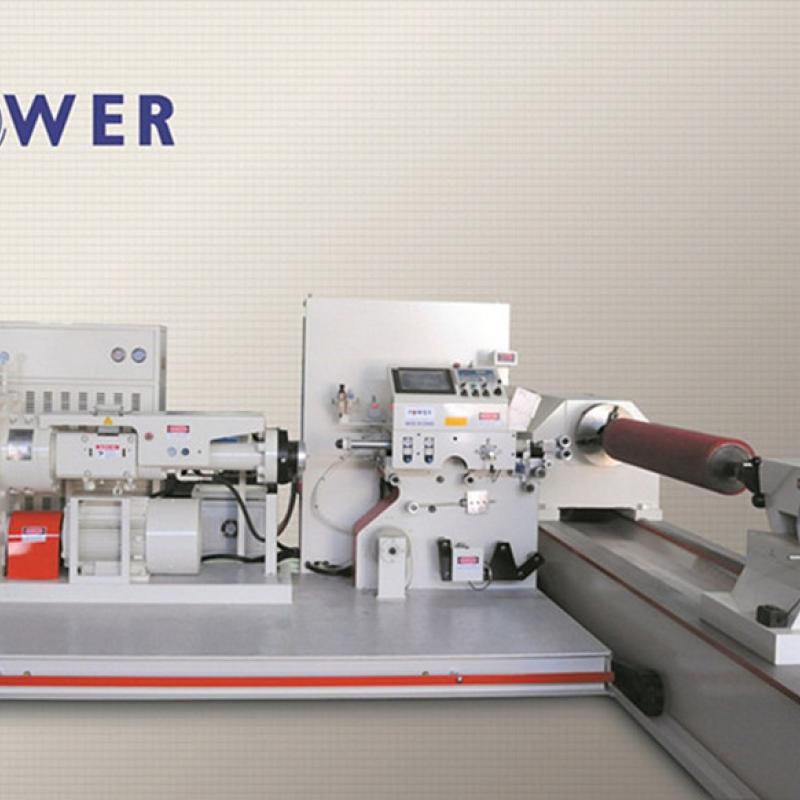

PSM series grinding machine for rubber roller processing is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe. After all, it is not the grinding machine; the moving spaces of the big and medium carriage table are larger than that of grinding machine.

Contacta ahora

Because of the all-spherical of the device feature, manufacturing unit custom designed rubber roller groover could make nearly all of the profile of rollers. for instance, parabolic crowning and concave, cosine crowning and concave, round, cone, coarse pitch, herringbone, diamond, without delay groove, horizontal groove and exclusive formations within the appended drawing.1.

Contacta ahora

Special Hickey-Picker Rubber RollerStrength enterprise adopts numerous special glue inventory made in america and germany to manufacture commercial robber rollers. for printing enterprise, there are alcohol plate moisturizing rubber roller, uv inker, rubber roller transmitting and sparing ink.

Contacta ahora

Product description1. The PCM-8040 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contacta ahora

Psf rubber roller surface measuring instrument is in particular designed and synthetic for rubber roller manufacturing firms. it's a kind of specific checking out tool encompass the maximum superior laser probe. it is able to make dimension for any apparent tolerance and roughness on ground of rubber rollers.

Contacta ahora

Because of the all-spherical of the tool function, production unit customized rubber curler groover should make nearly all of the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, at once groove, horizontal groove and exceptional formations in the appended drawing.1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2.

Contacta ahora

PTM-1510 Industrial Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weeksWith the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances.

Contacta ahora

Rubber strainerRubber strainer is the usage of screw push, conveying the function of the glue or recycled gum impurities within the removal of the machinery.it particularly consists of screw, barrel, glue head and transmission device.the filter head is geared up with orifice plate and clear out net, the orifice plate is used to aid the rubber strainer internet and is the discharging port, its aperture is four~8mm, and it is the conical hole which expands alongside the drift path of the rubber cloth.the duration-diameter ratio of the screw in the filter out gadget is set 5.Selection of Rubber F

Contacta ahora

About usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production. It was set up in 1998, and now is the main base in our country for manufacturing rubber roller special machine.Power Company is a professional producer engaged in rubber roller manufacturing equipment, with a large production scale and strong technical force.

Contacta ahora

1.especially designed with the useful resource of strength for particular first-rate manage of rubber rollers.2. inclusive of the maximum advanced laser probe. making dimension for any obvious tolerance and roughness on floor of rubber rollers.3. connecting to pc effortlessly for facts's transmission and evaluation.4. consumer first-class working device.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contacta ahora