Textile Printing RollerPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2.

Contacta ahora

Web Press Rubber Roller For PrinterWith the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contacta ahora

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature perfor

Contacta ahora

High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistanceApplications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such&n

Contacta ahora

Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistance Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Shipping:

Contacta ahora

Functions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersShipping:

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Special Hickey-Picker Rubber RollerStrength enterprise adopts numerous special glue inventory made in america and germany to manufacture commercial robber rollers. for printing enterprise, there are alcohol plate moisturizing rubber roller, uv inker, rubber roller transmitting and sparing ink.

Contacta ahora

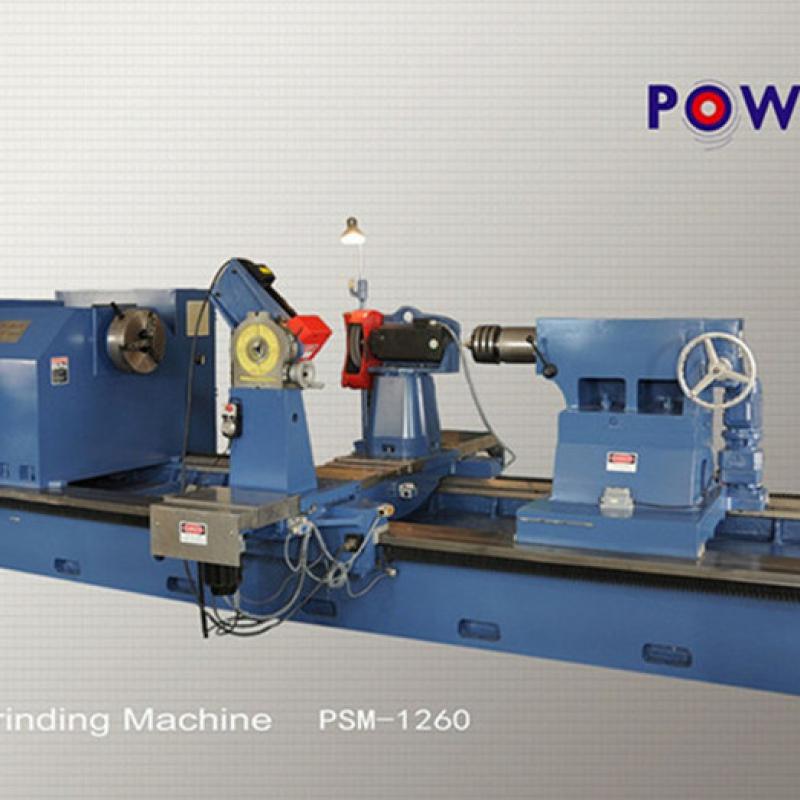

Factory Rubber Roller Grinding Machine For Textile The feature of PSM series factory rubber roller grinding machine for textile 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacta ahora

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersShipping:

Contacta ahora

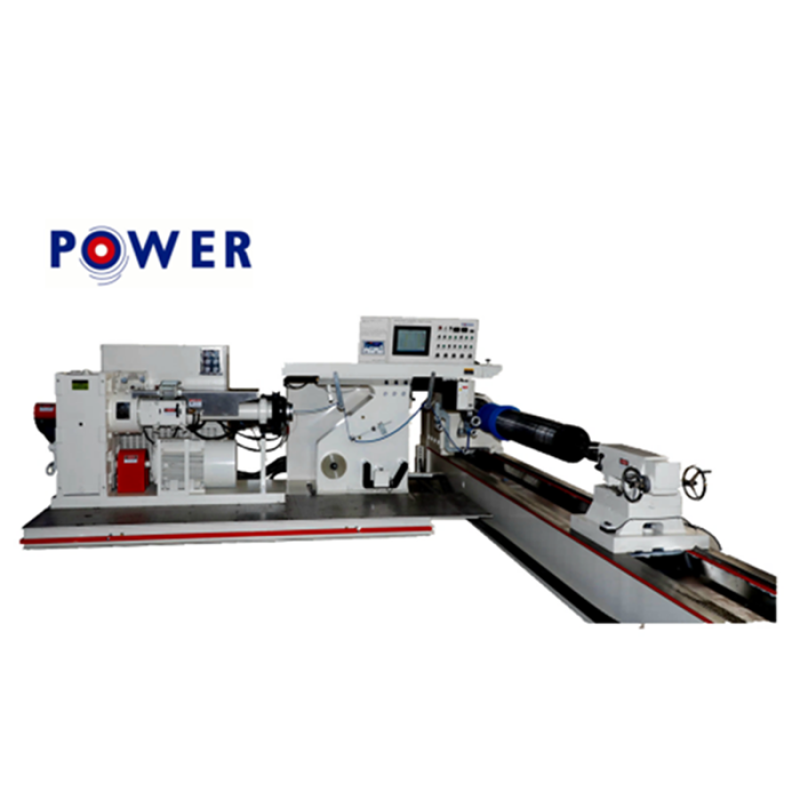

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding gadget is specifically designed and synthetic to replace the beyond curler processing method by way of metallic production equipment. set up grinding head at the engine lathe is the beyond approach to fabricate roller, which the high-quality of roller is hard to attain the requirement of the present widespread. the primary cause lies inside the shape of lathe. in the end, it isn't the grinding gadget; the shifting spaces of the large and medium carriage desk are large than that of grinding device.

Contacta ahora

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contacta ahora

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersPackaging & Shipping 1. Outside package: Standard export wooden cases 2. Inner package: Stretch filmShipping detail:Within 2-4 weeksOur Services:1. Installation service.2. Maintenance service.3. Technical support online service provided.4.

Contacta ahora

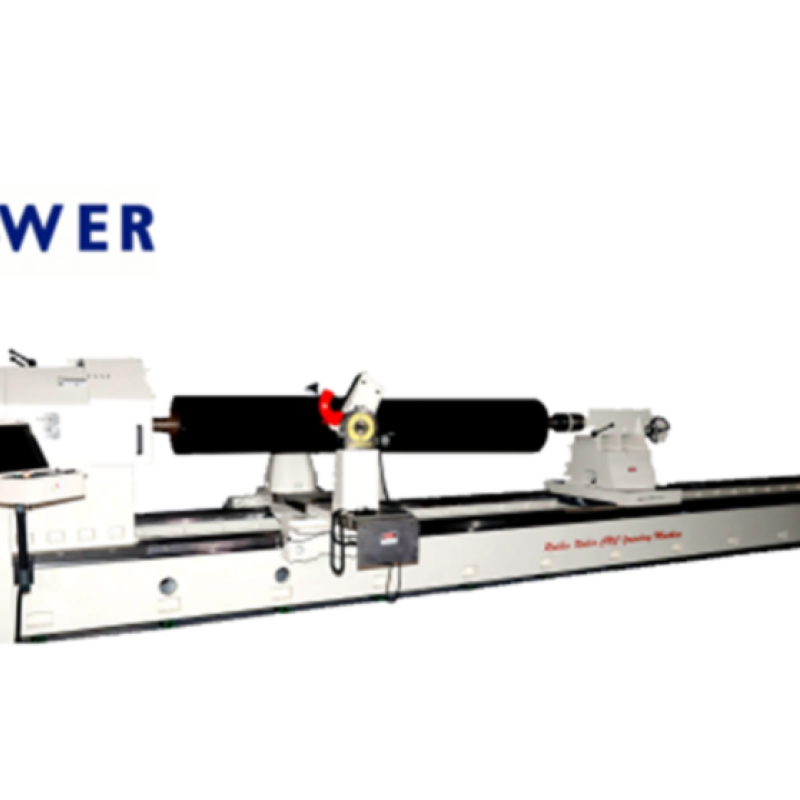

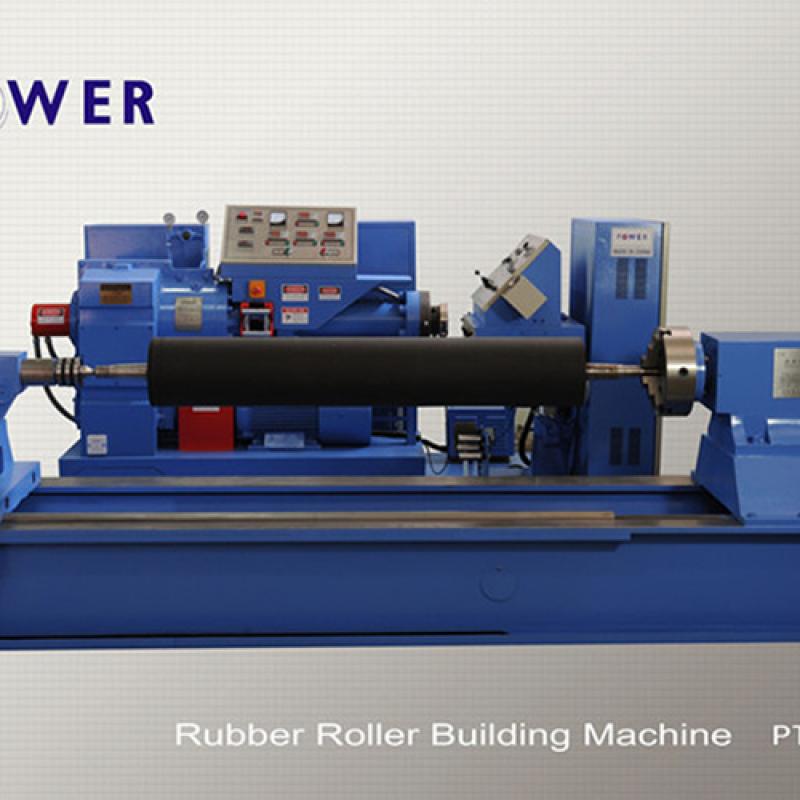

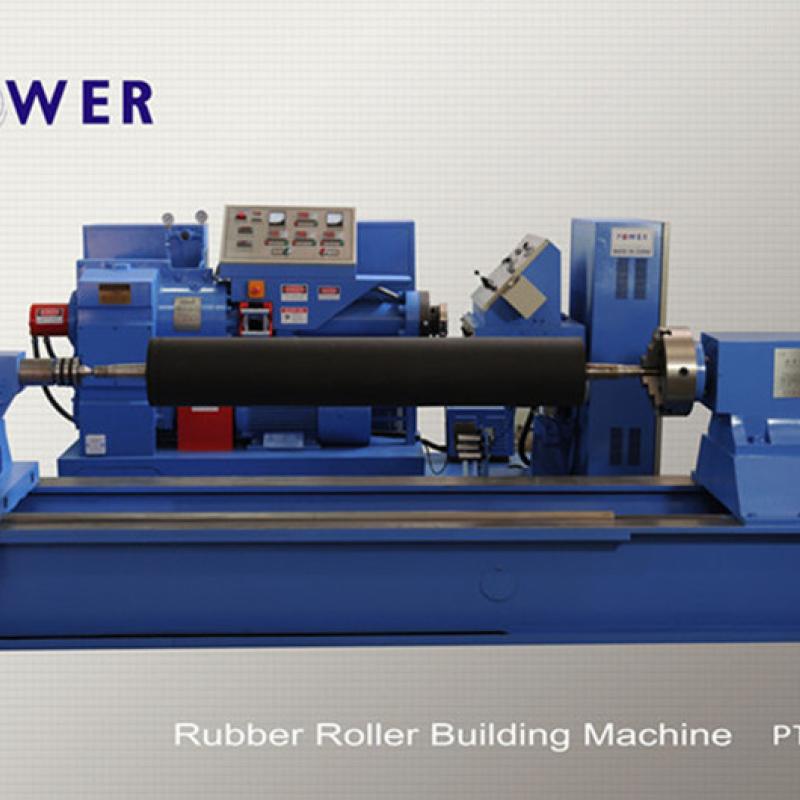

Product descriptionFeatures of PTM-1080 Steel Textile Dyeing Rubber Roller Wrapping Machine1. Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contacta ahora

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistancePackaging & Shipping 1. Outside package: Standard export wooden cases 2.

Contacta ahora

QUALITY CONTROL Precisely checked with our own made PSF series rubber roller laser measuring instrument. APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.PRODUCTIONBeing extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality

Contacta ahora

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Web Press Rubber Roller For PrinterWith the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.With the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contacta ahora

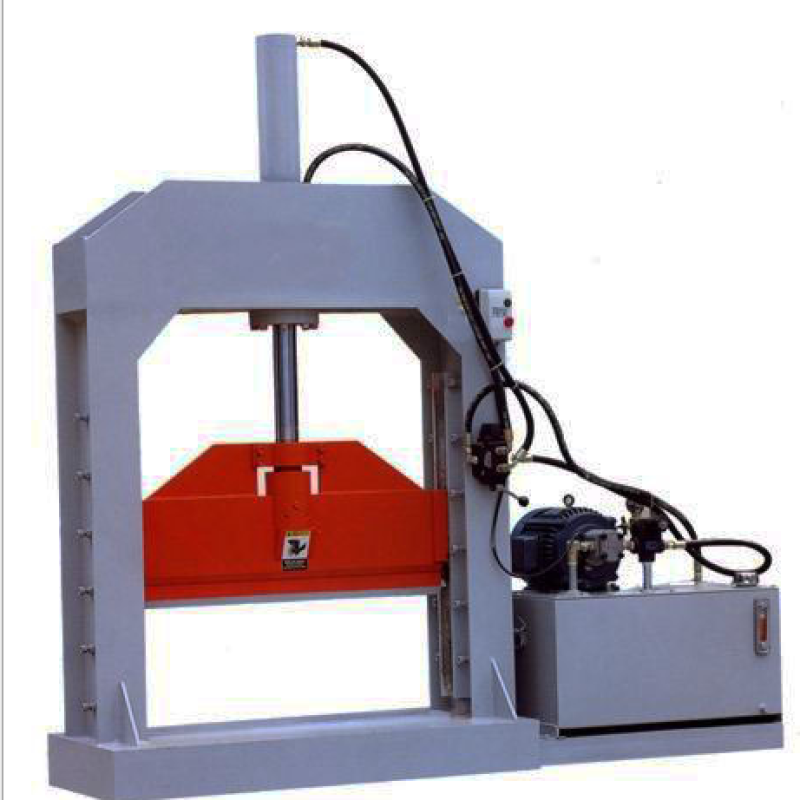

The Hydraulic rubber cutting machine The Hydraulic rubber cutting machine mainly has the cutting glue knife, the machine frame, the work oil cylinder, the base, the auxiliary work table and the hydraulic system, the electrical system and so on part composes, the cutting glue knife base is equipped with the nylon or the soft lead backing plate, protects the cutting knife the blade.Raw gum, with artificial glue in the cutting knife below, and then press the Start button, then the cutting knife in the piston rod driven by the slide along the rack down the rubber material cut.The ra

Contacta ahora

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contacta ahora

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

Product Description:Mainly used for balance verification of large and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and other rotating workpieces.The machine adopts ring belt drive or gear box universal joint transmission, and frequency conversion motor drive to ensure the balanced quality and precision of the workpiece.The machine has the characteristics of wide speed range, large driving power and high working efficiency. Model NumberPHQ-3000HPHW-3000H2460-10000HTransmissionBelt DriveUniversal JointUniversal JointWorkpiece weight range (kg)3000300010000Workpiece Ma

Contacta ahora

PRODUCTIONBeing extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality. Our products have sophisticated production technologies and excellent product quality, being recognized by domestic and foreign users.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora