Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

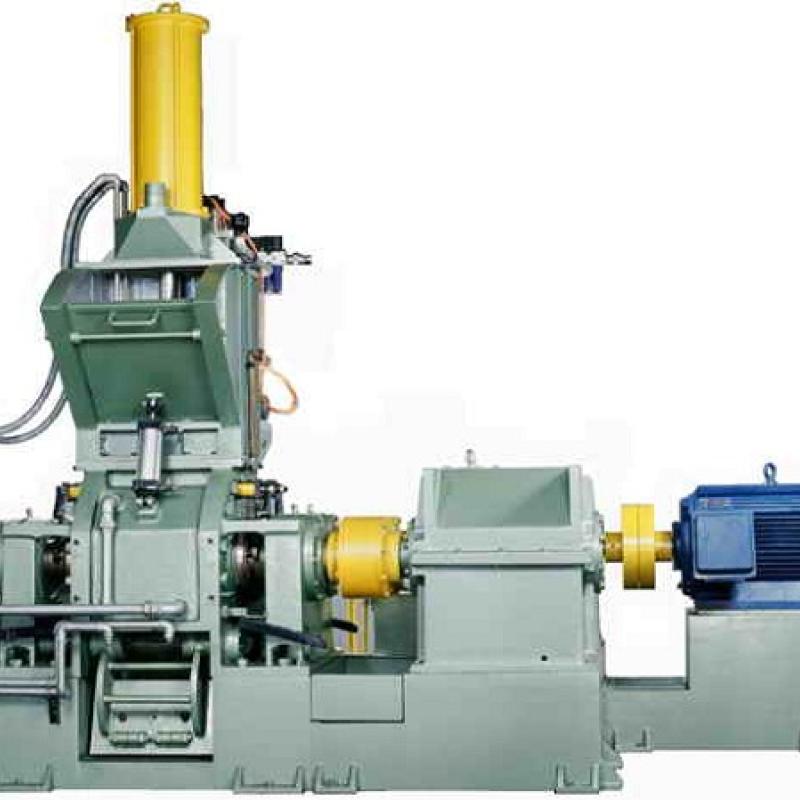

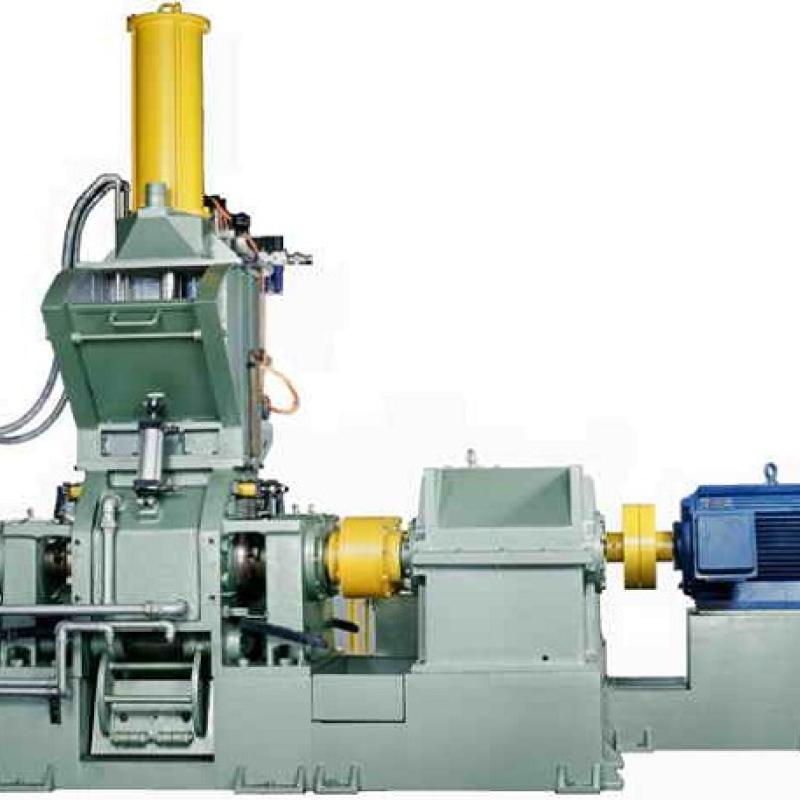

Banbury Rubber machineBanbury rubber device is a type of high electricity clearance mixing device evolved on the premise of the open mixer milll.consequently, the emergence of banbury rubber machine is a rubber machinery, an vital achievement, nevertheless is the plastic refining and mixing of the everyday critical equipment, continues to be in consistent improvement and improvement. Our Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Spare parts replacement and repair

Contacta ahora

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

Rubber banbury inner mixer is a sort of excessive strength clearance mixing device evolved on the premise of the open mixer milll.therefore, the emergence of rubber banbury internal mixer is a rubber machinery, an crucial fulfillment, nonetheless is the plastic refining and combining of the typical vital system, continues to be in steady improvement and development.Packaging & ShippingPacking details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacta ahora

Rubber banbury inner mixer is a sort of excessive strength clearance mixing device evolved on the premise of the open mixer milll.therefore, the emergence of rubber banbury internal mixer is a rubber machinery, an crucial fulfillment, nonetheless is the plastic refining and combining of the typical vital system, continues to be in steady improvement and development.Our Servicesmatch:1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contacta ahora

Banbury Rubber machineBanbury Rubber machine is a kind of high strength clearance mixing equipment developed on the basis of the open mixer milll.Therefore, the emergence of Banbury Rubber machine is a rubber machinery, an important achievement, still is the plastic refining and mixing of the typical important equipment, is still in constant development and improvement. Our Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Spare parts replacement and repair ser

Contacta ahora

Used Open Rubber Mixing Mill 18" Two Roll / Second-hand Open Rubber Mixing Machine / Used Open Rubber Mixer Mill / Used Open Rubber Mixing MillUsed for rubber mixing and feeding for the next proocess. Second hand used machine with good condition.Product description18" Second-hand Used Rubber Open Mixing MillAbout usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacta ahora

Banbury Rubber mixer machineThe scope application of internal mixer is very wide, such as rubber, synthetic rubber, resin, asphalt, cellulose,P.V.C.E.V.A. raw materials such as P.E, can in the shortest time to complete mixing. The Rubber banbury internal mixer machine body structure is strong and durable. The powder stop equipment can effectively prevent the leakage of raw materials and compound agents through special design. It has long service life, simple operation, good effect and easy maintenance, and it is also very convenient to replace the worn parts.

Contacta ahora

Banbury Rubber mixer machineThe scope application of internal mixer is very wide, such as rubber, synthetic rubber, resin, asphalt, cellulose,P.V.C.E.V.A. raw materials such as P.E, can in the shortest time to complete mixing. The Rubber banbury internal mixer machine body structure is strong and durable. The powder stop equipment can effectively prevent the leakage of raw materials and compound agents through special design. It has long service life, simple operation, good effect and easy maintenance, and it is also very convenient to replace the worn parts.

Contacta ahora

About usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production. It was set up in 1998, and now is the main base in our country for manufacturing rubber roller special machine.Power Company is a professional producer engaged in rubber roller manufacturing equipment, with a large production scale and strong technical force.

Contacta ahora

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

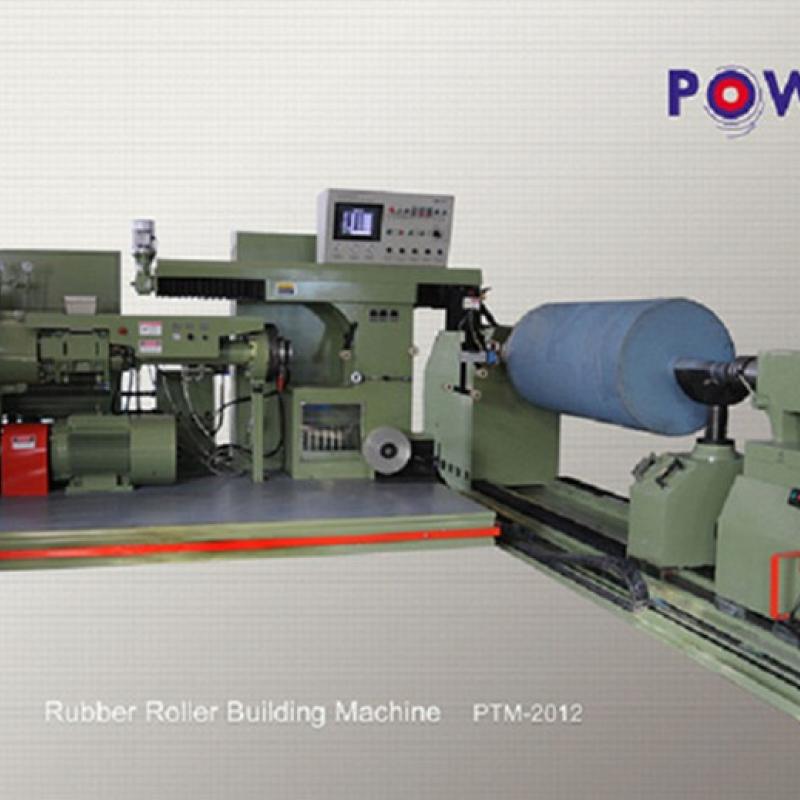

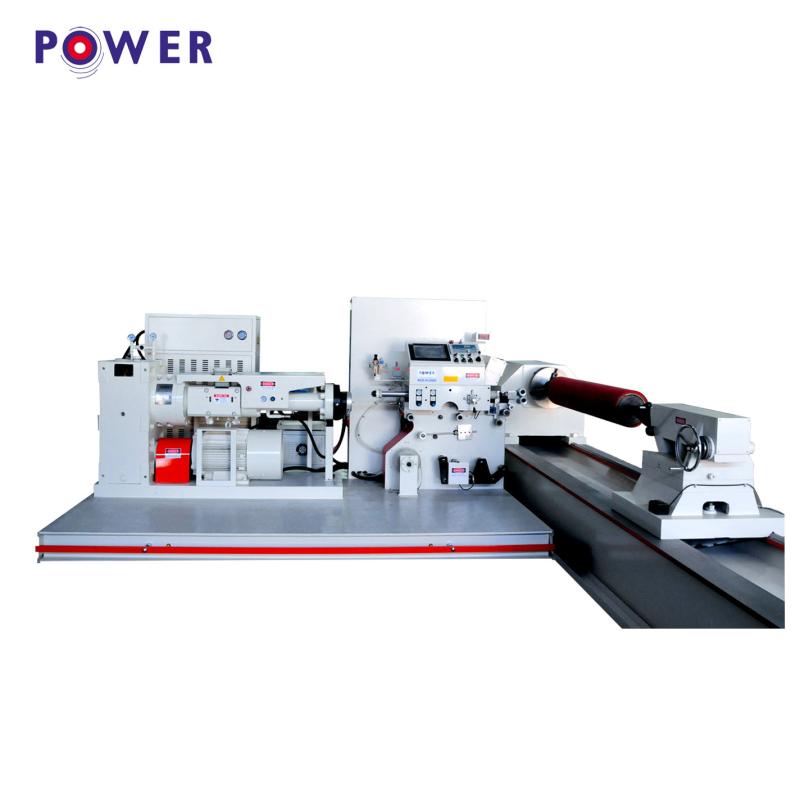

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contacta ahora

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

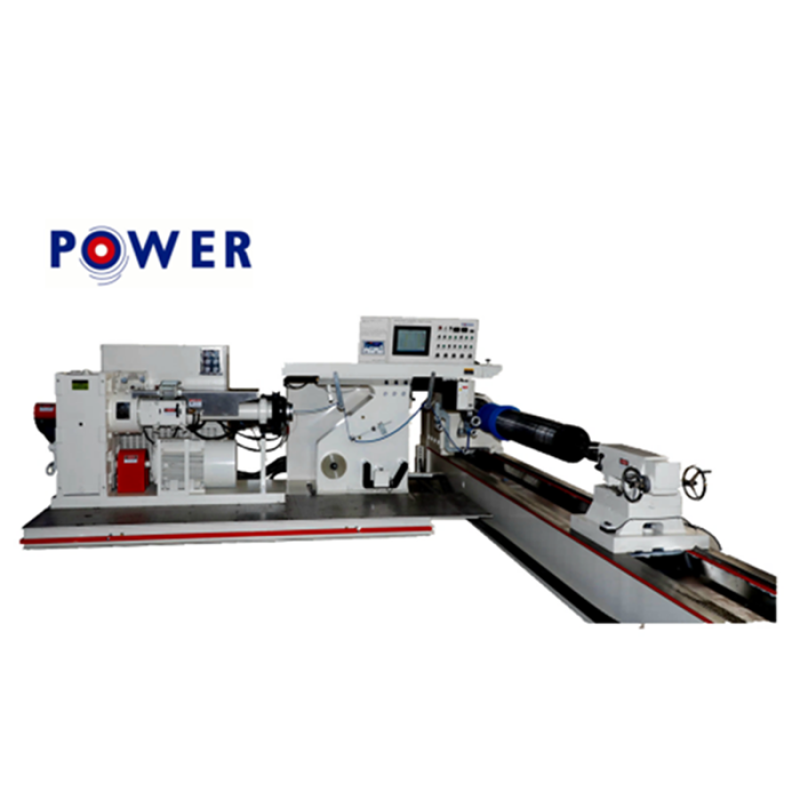

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

Product descriptionFeatures of PTM-1080 Steel Textile Dyeing Rubber Roller Wrapping Machine1. Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contacta ahora

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber roller Covering Machine PTM-2012 model is suitable for processing paper mill, mine transportation and heavy industrial rolls.2. Our rubber roller building machine equipped with E350CS power extruder and a complete industrial cooling system.3. The Rubber Roller Covering Machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

Product description1. the pcm-8040 model is suitable for renewing business rubber rollers.2. doing away with old rubber by special ring cutter.3. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding manner.Four. perfectly maintaining the unique dynamic stability of the roller middle.Five. giving extra dependable guarantee for the bonding of the rubber and metal cores.6. saving charges and labors with this progressed manufacturing device.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

The feature of PSM series grinding machine for rubber roller processing1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max. linear speed of grinding head is over 90m/s.

Contacta ahora

The Hydraulic rubber cutting machine The hydraulic rubber reducing system especially has the cutting glue knife, the device frame, the paintings oil cylinder, the bottom, the auxiliary work table and the hydraulic machine, the electric system and so forth component composes, the cutting glue knife base is ready with the nylon or the gentle lead backing plate, protects the slicing knife the blade.uncooked gum, with artificial glue inside the slicing knife below, and then press the begin button, then the cutting knife in the piston rod driven via the slide alongside the rack down the rubber

Contacta ahora

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contacta ahora

Web Press Rubber Roller For PrinterWith the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contacta ahora