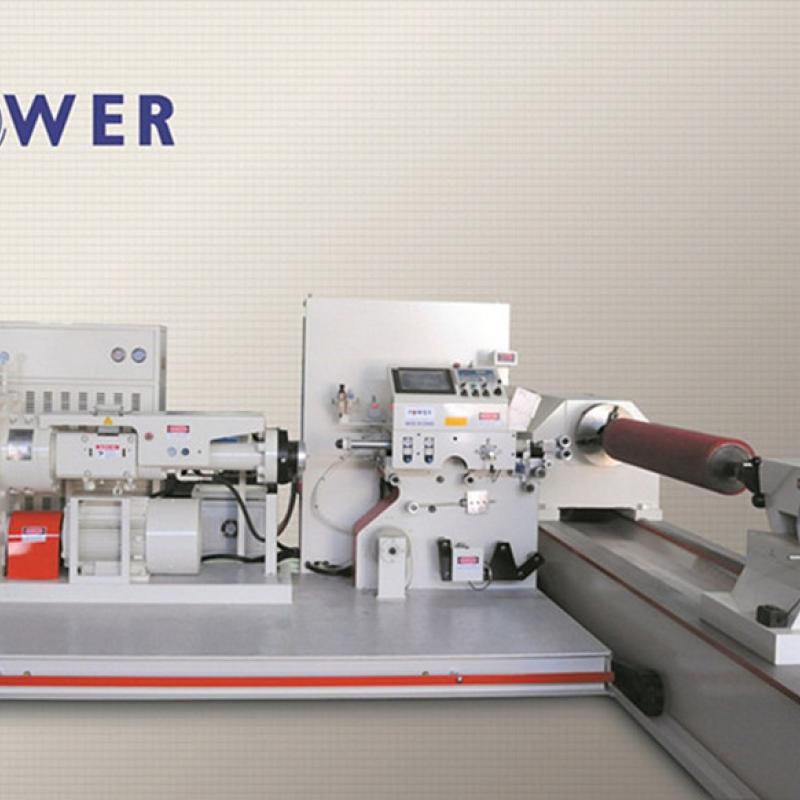

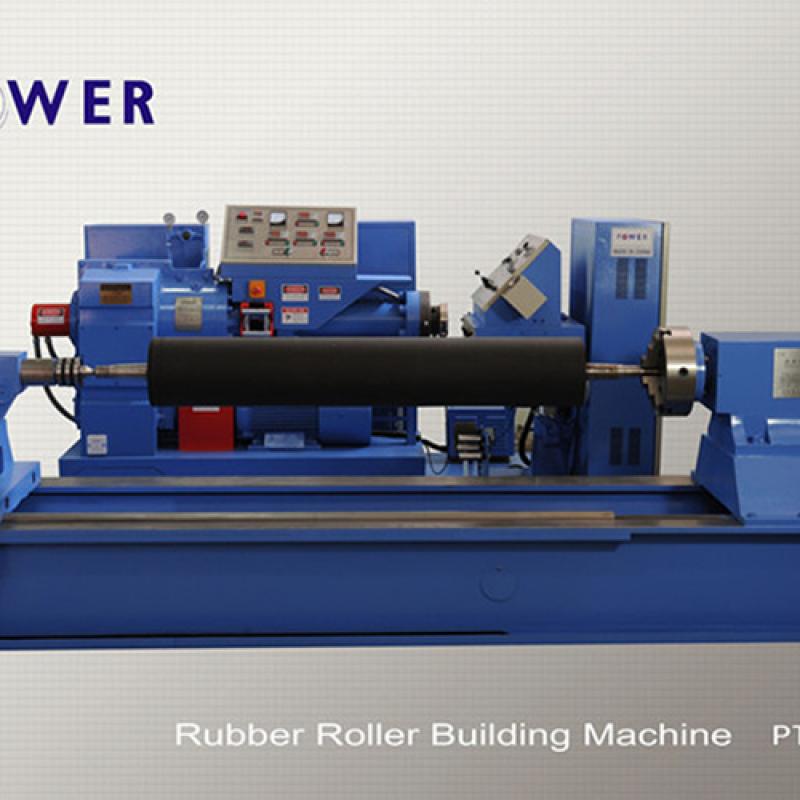

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contacta ahora

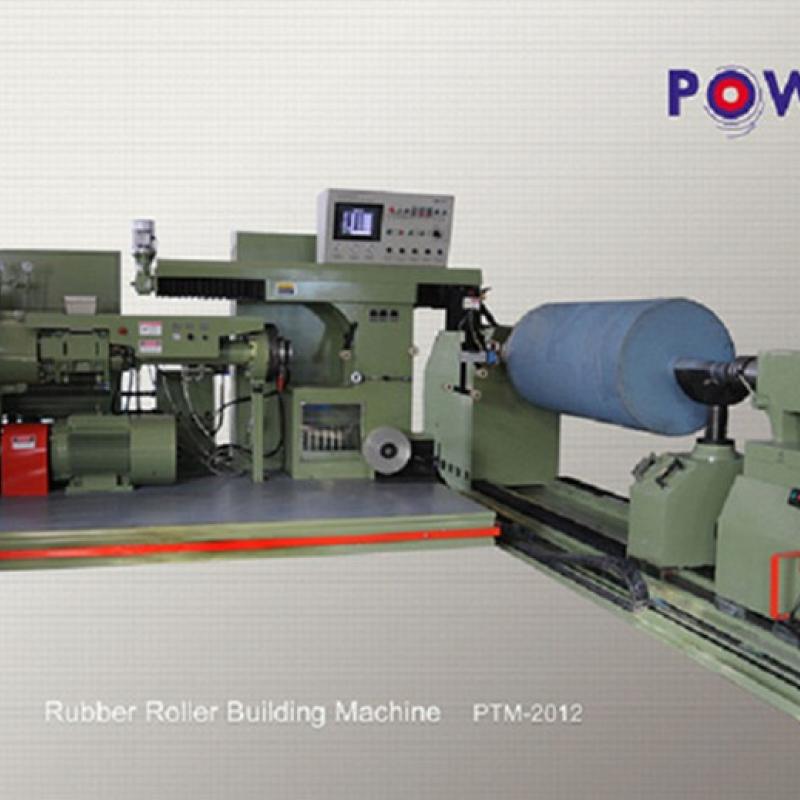

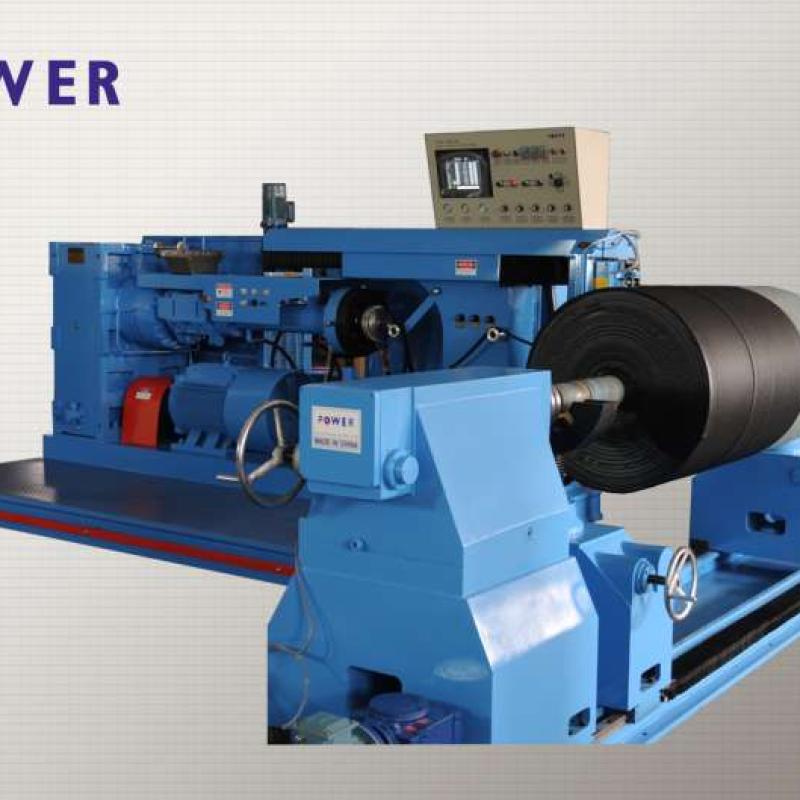

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

Product descriptionFeatures of PTM-1080 Steel Textile Dyeing Rubber Roller Wrapping Machine1. Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contacta ahora

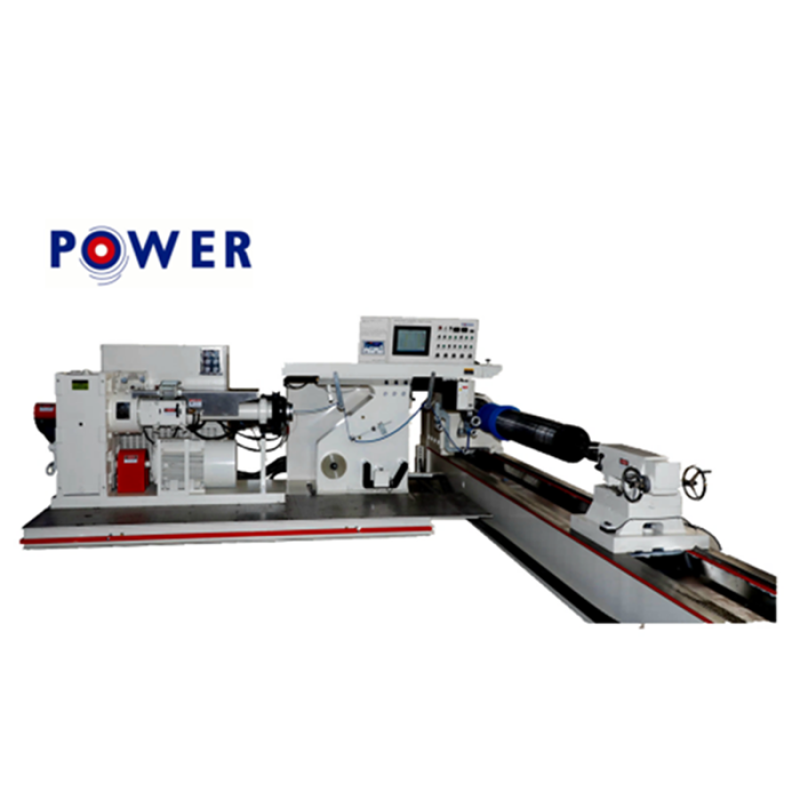

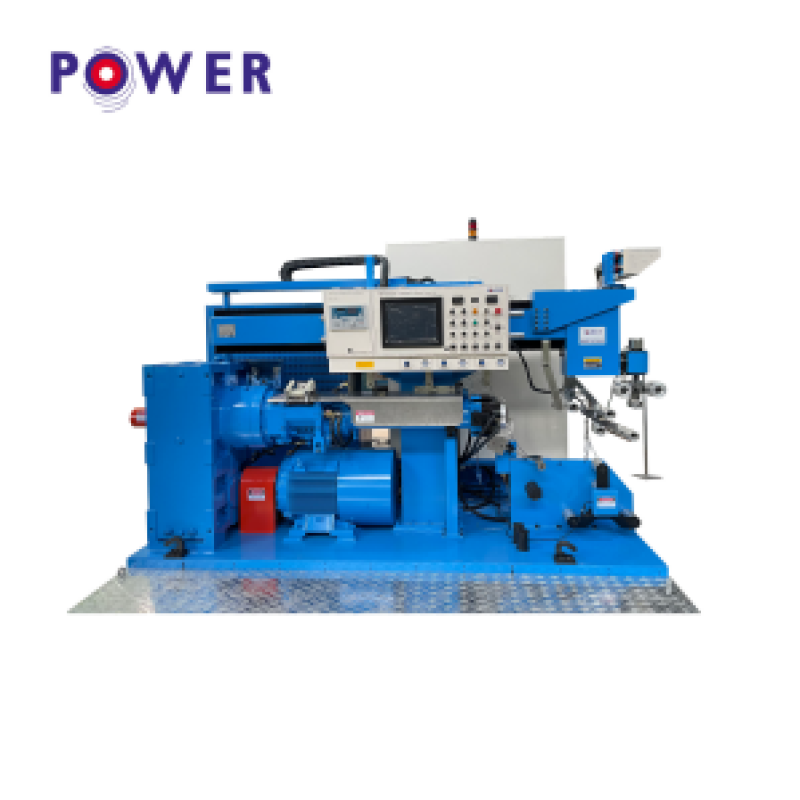

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contacta ahora

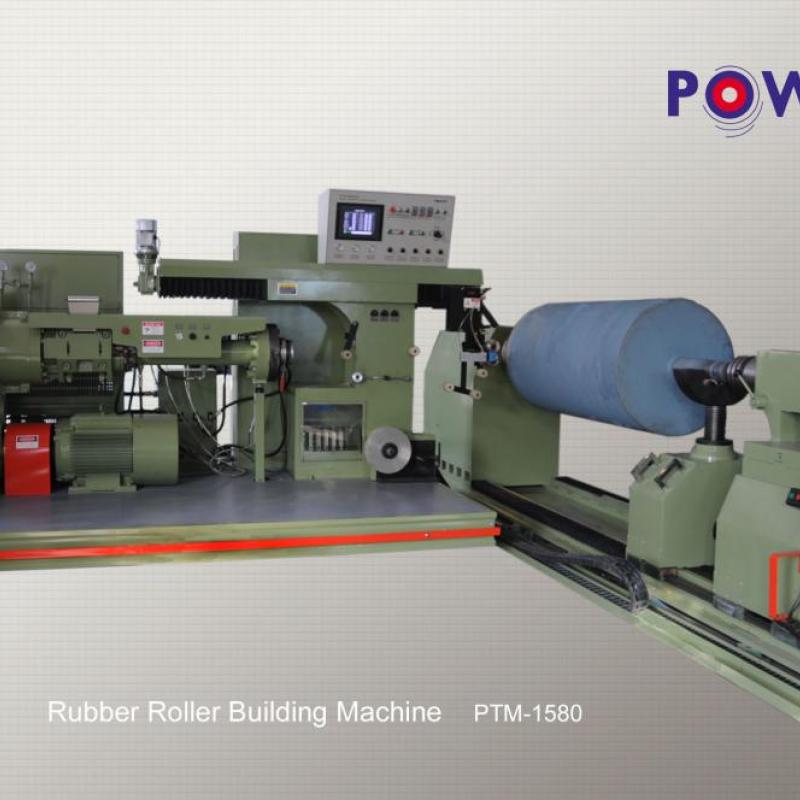

Product descriptionFeatures of PTM-1560 Rubber Roller Wrapping Machine For Paper Industry1. Rubber roller winding machine PTM-1580 model is suitable for paper making industry.2. Our rubber roller winding machine equipped with E350CS power extruder and a complete industrial cooling system.3. The rubber roller winding machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contacta ahora

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber roller Covering Machine PTM-2012 model is suitable for processing paper mill, mine transportation and heavy industrial rolls.2. Our rubber roller building machine equipped with E350CS power extruder and a complete industrial cooling system.3. The Rubber Roller Covering Machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contacta ahora

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contacta ahora

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contacta ahora

Textile Printing RollerPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2.

Contacta ahora

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contacta ahora

Psf rubber curler surface measuring instrument is specifically designed and manufactured for rubber roller production firms. it's a kind of unique testing device include the most advanced laser probe. it can make dimension for any apparent tolerance and roughness on floor of rubber rollers.

Contacta ahora

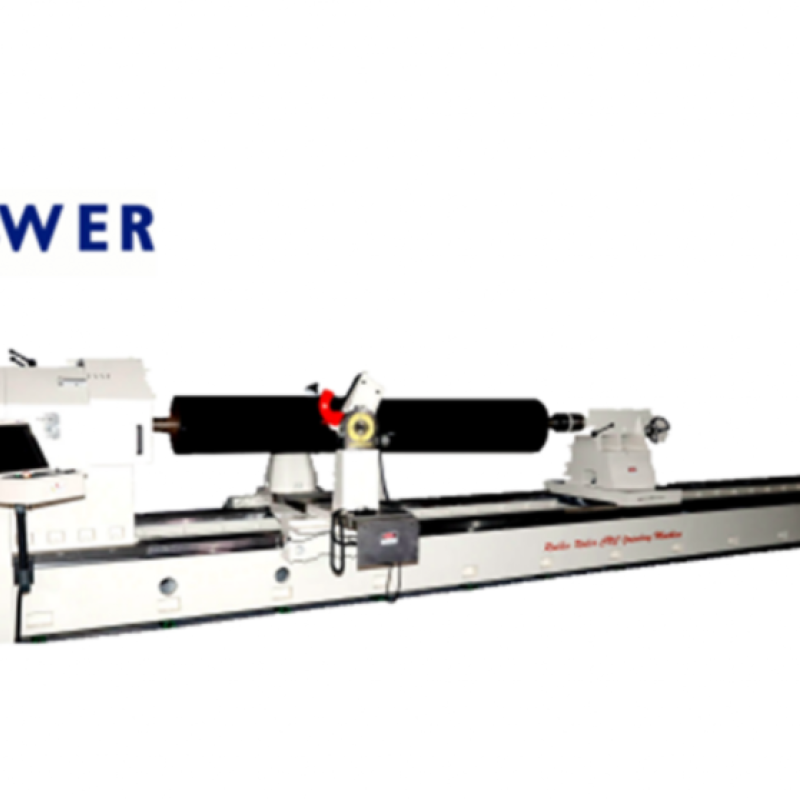

1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2. the contemporary cnc gadget can without problems perform more than 35 shapes on the rubber roller floor, which incorporates: crowning, concave,and wave grindings; herringbone, diamond, directly groovings, and many others. 3. far off problem fixing feature availabe.4.

Contacta ahora

Product descriptionFeatures of PTM-8060 Rubber Roller Coating Machine Price1.Applicable to production of Rubber Rollers in heavy industry, such as transmission rubber rollers in steel and steel deepprocessing industry,textile industry,printing and dyeing industry and so on.2.Equipped with E300CS 76 cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with all hardness.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPT

Contacta ahora

Web Press Rubber Roller For PrinterWith the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.With the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contacta ahora

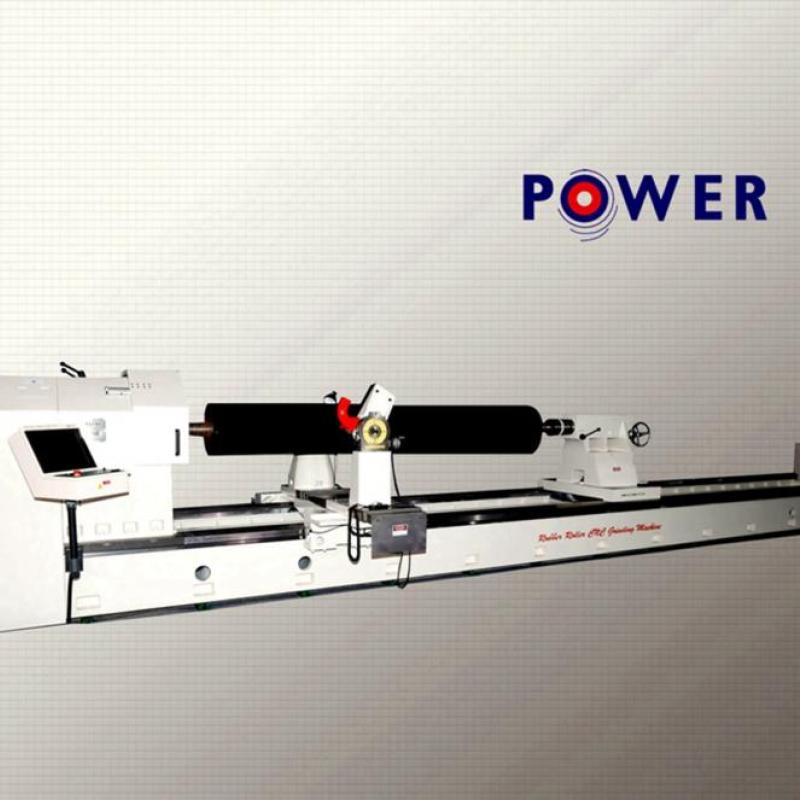

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contacta ahora

Product description1. This equipment is designed as a follow up machine of our PSM series for the rubber roller surface refining process.2. Meeting critical requirements on the surface smoothness by choosing the abrasive band with different granularity.3. The geometric size of rubber roller will remain unchanged.4. The operating system is simple and easy-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contacta ahora

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contacta ahora