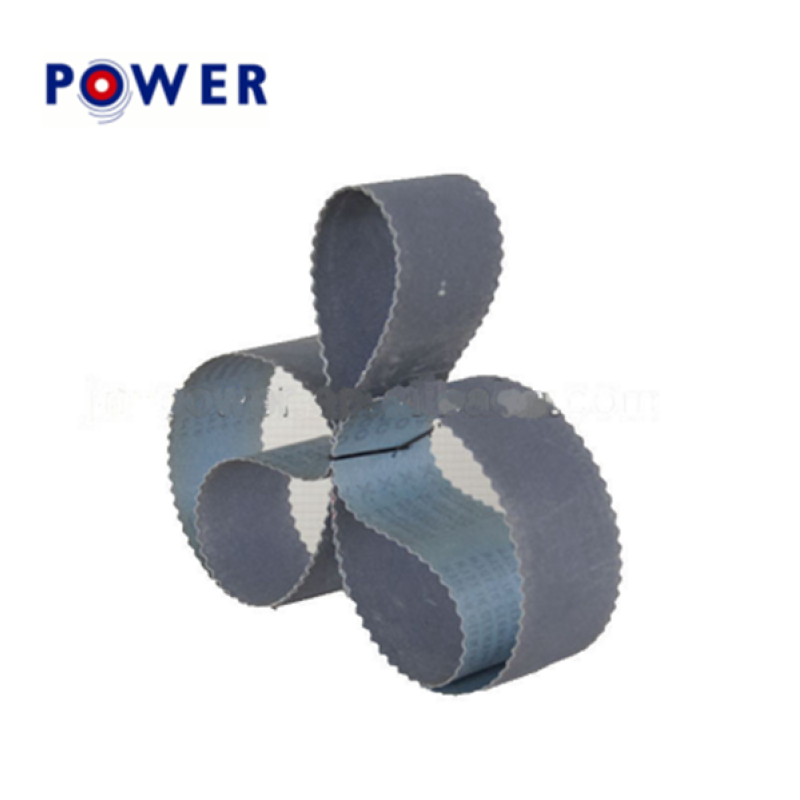

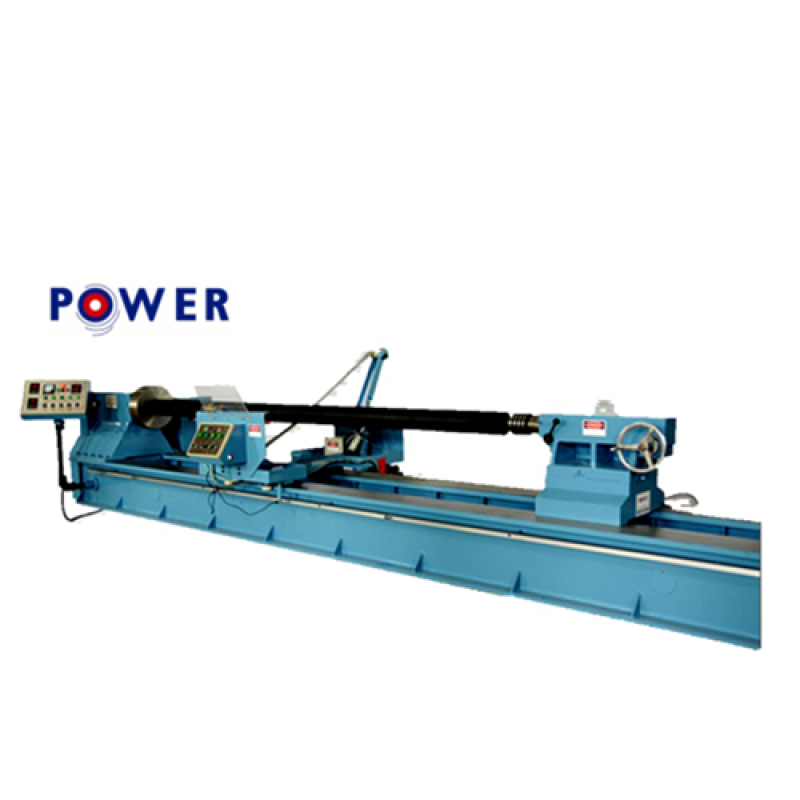

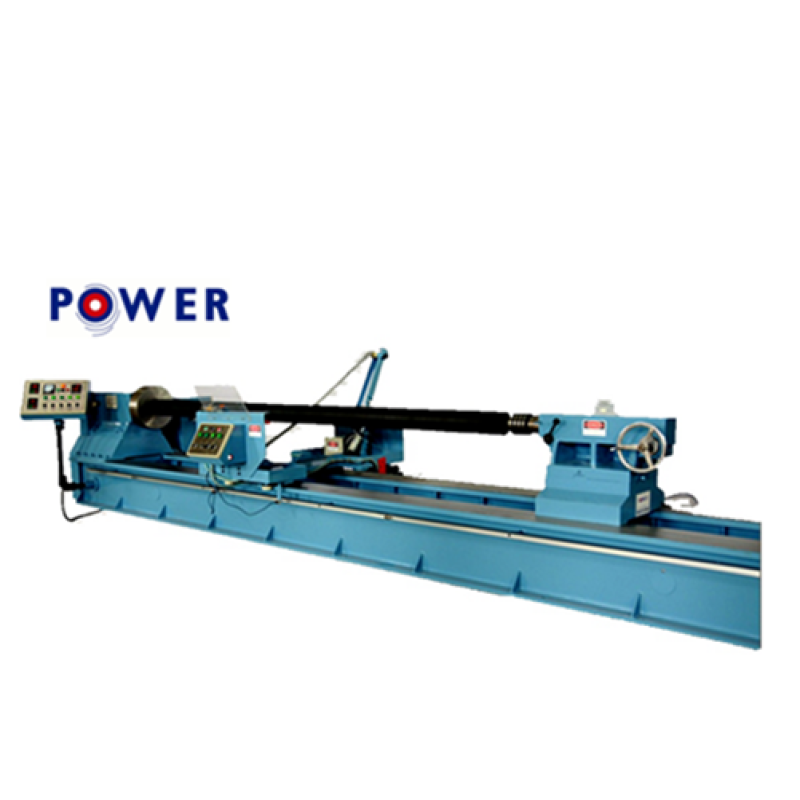

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contacta ahora

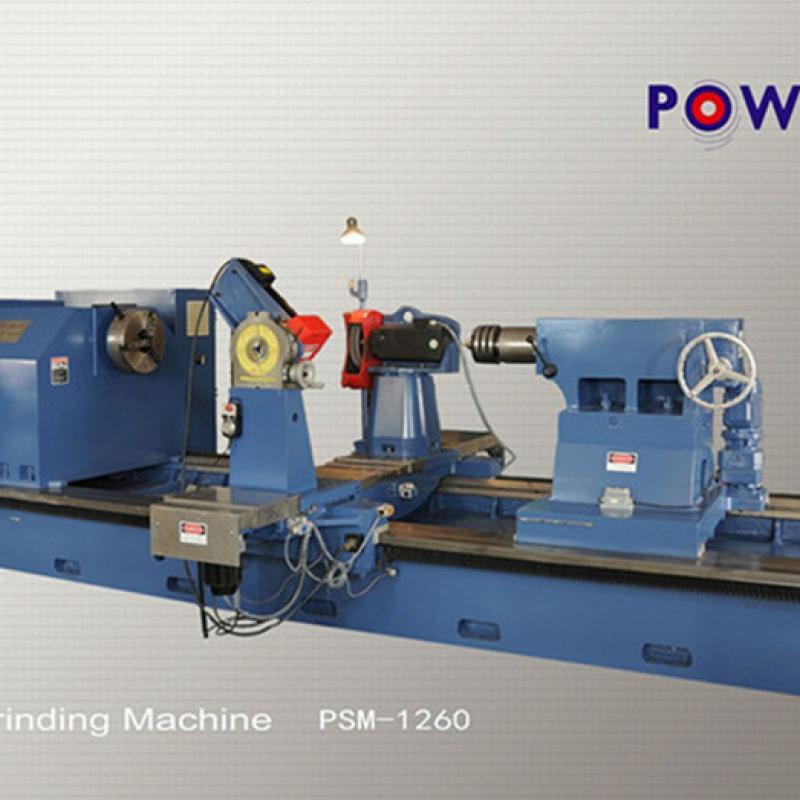

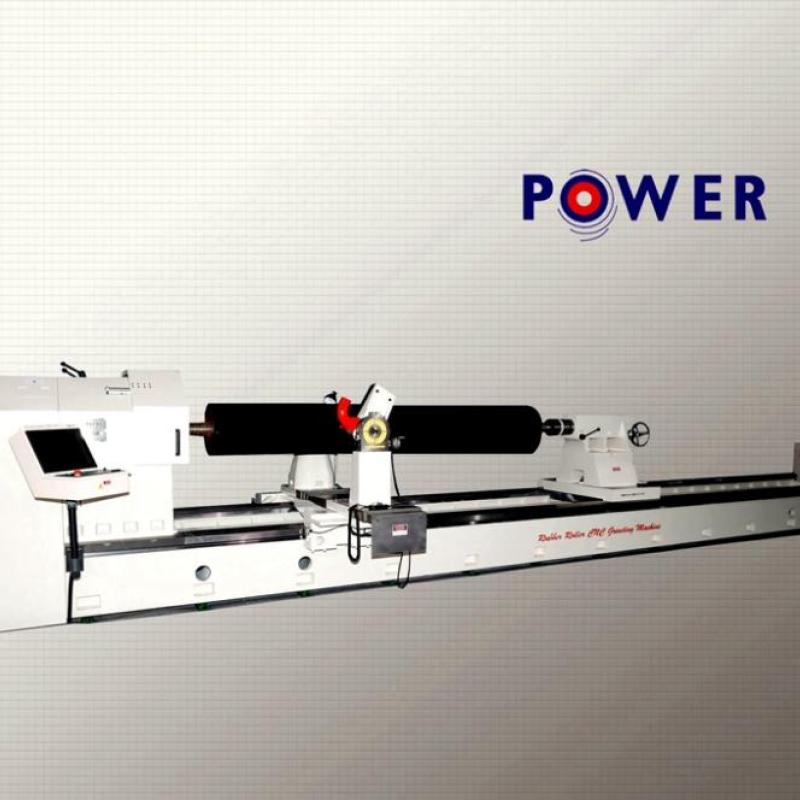

Factory Automatic Cylindrical Roll GrinderThe feature of PSM series Factory Automatic Cylindrical Roll Grinder1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max.

Contacta ahora

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacta ahora

1.in particular designed through energy for precise pleasant manage of rubber rollers.2. along with the most superior laser probe. making dimension for any apparent tolerance and roughness on surface of rubber rollers.3. connecting to computer without problems for statistics's transmission and analysis.4. person friendly running gadget.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contacta ahora

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;Three. there are more than one sorts, duration and styleCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and styleProduct use:Shipping photos:

Contacta ahora

Product description1. this gadget is designed as a follow up device of our psm collection for the rubber roller floor refining device.2. assembly critical requirements on the ground smoothness thru selecting the abrasive band with specific granularity.3. the geometric length of rubber roller will stay unchanged.Four. the running device is simple and smooth-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contacta ahora

Product description1. this gadget is designed as a follow up device of our psm collection for the rubber roller floor refining device.2. assembly critical requirements on the ground smoothness thru selecting the abrasive band with specific granularity.3. the geometric length of rubber roller will stay unchanged.Four. the running device is simple and smooth-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

Psf rubber curler surface measuring instrument is specifically designed and manufactured for rubber roller production firms. it's a kind of unique testing device include the most advanced laser probe. it can make dimension for any apparent tolerance and roughness on floor of rubber rollers.

Contacta ahora

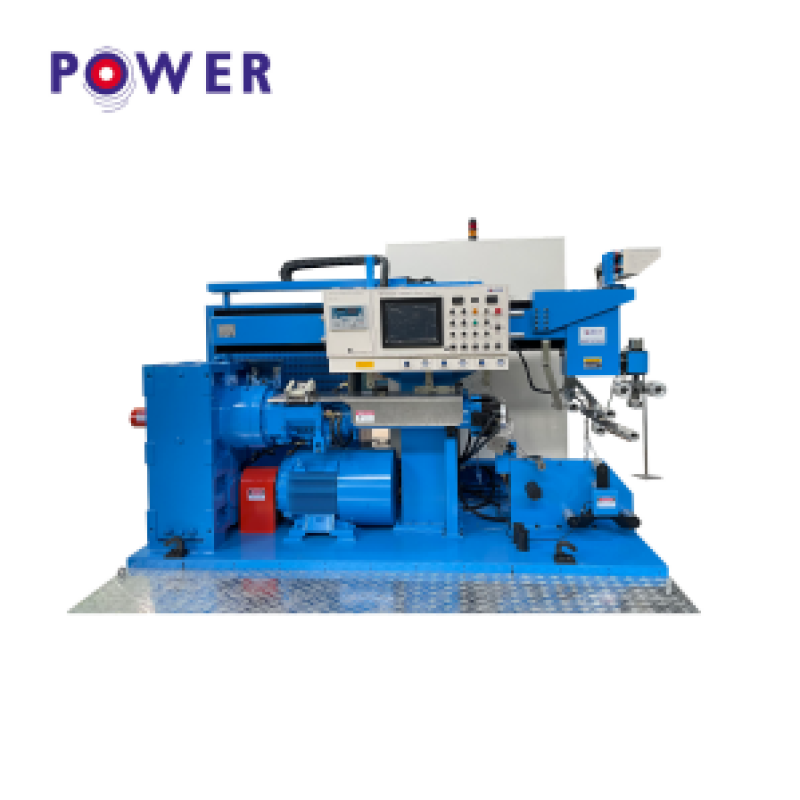

Used Open Rubber Mixing Mill 18" Two Roll / Second-hand Open Rubber Mixing Machine / Used Open Rubber Mixer Mill / Used Open Rubber Mixing MillUsed for rubber mixing and feeding for the next proocess. Second hand used machine with good condition.Product description18" Second-hand Used Rubber Open Mixing MillAbout usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacta ahora

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contacta ahora

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacta ahora

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding gadget is specifically designed and synthetic to replace the beyond curler processing method by way of metallic production equipment. set up grinding head at the engine lathe is the beyond approach to fabricate roller, which the high-quality of roller is hard to attain the requirement of the present widespread. the primary cause lies inside the shape of lathe. in the end, it isn't the grinding gadget; the shifting spaces of the large and medium carriage desk are large than that of grinding device.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contacta ahora

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past roller processing technique with the aid of using manner of steel manufacturing equipment. installation grinding head on the engine lathe is the past technique to manufacture curler, which the superb of curler is tough to gain the requirement of the existing widespread. the number one reason lies withinside the form of lathe.

Contacta ahora

Factory Price Rubber Roller PolisherMore than 8 merchandise have been provided countrywide or shandong provincial stage product prizes and three scientific-studies achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Equipment video:Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5.

Contacta ahora

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacta ahora

Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2. meeting essential requirements at the floor smoothness via choosing the abrasive band with distinctive granularity.3. the geometric length of rubber curler will remain unchanged.4. the working device is easy and clean-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacta ahora

Product descriptionCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: Outside package: Standard export wooden cases.Inner package: Stretch film.Shipping detail: Within 2-4 weekOur ServicesInstallation service.Maintenance service.Technical support online service provided.Technical files service provided.On-site training service provided.Renew service provided.Product use:Shipping photos:

Contacta ahora

PSM-8040 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past curler processing technique with the aid of using the usage of manner of metallic manufacturing device. set up grinding head at the engine lathe is the beyond approach to manufacture roller, which the brilliant of roller is tough to benefit the requirement of the triumphing full-size. the number one reason lies withinside the shape of lathe.

Contacta ahora

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contacta ahora

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contacta ahora