With the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances. numerous operating processes had been introduced to make certain maximum reliable high-quality.With the guideline of excellent first, clients the best, electricity enterprise offers to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of latest base gum and corollary offerings for system manufacturers.Packaging & ShippingPackaging detail: 1.

Contacta ahora

Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weeksWith the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances.

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

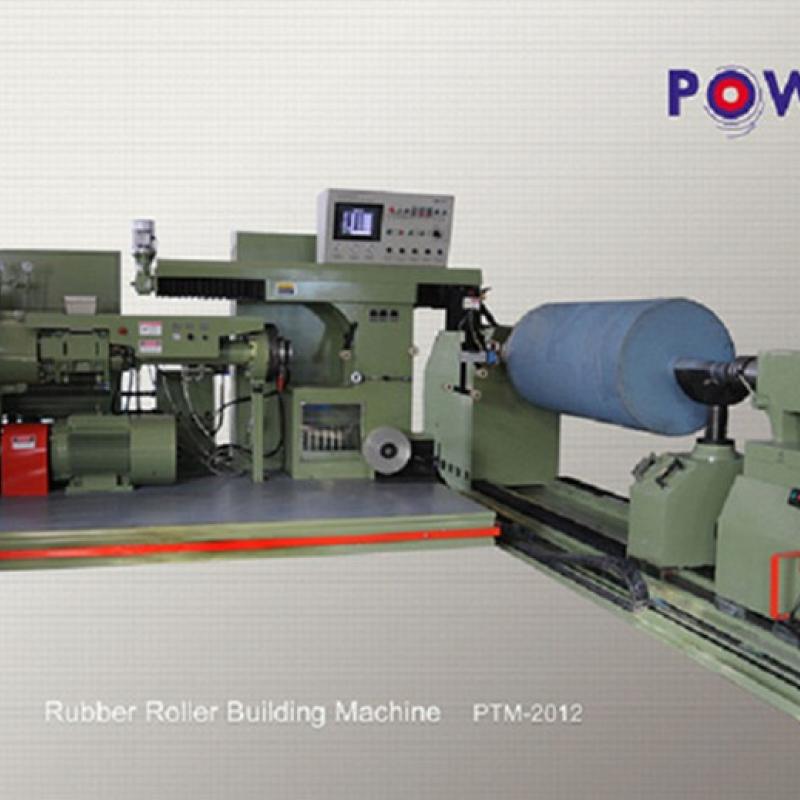

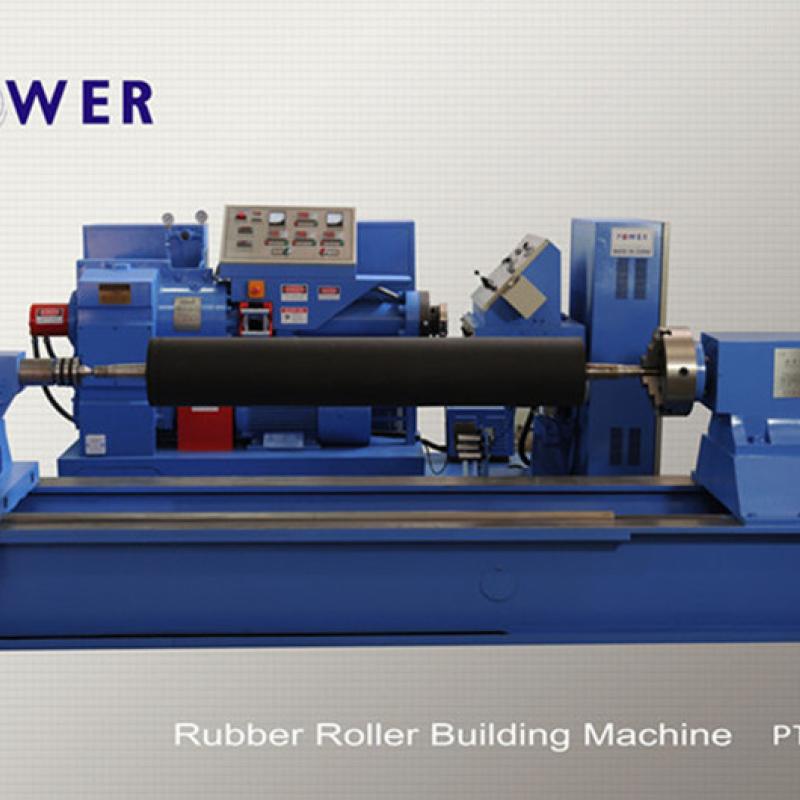

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contacta ahora

Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber roller Covering Machine PTM-2012 model is suitable for processing paper mill, mine transportation and heavy industrial rolls.2. Our rubber roller building machine equipped with E350CS power extruder and a complete industrial cooling system.3. The Rubber Roller Covering Machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contacta ahora

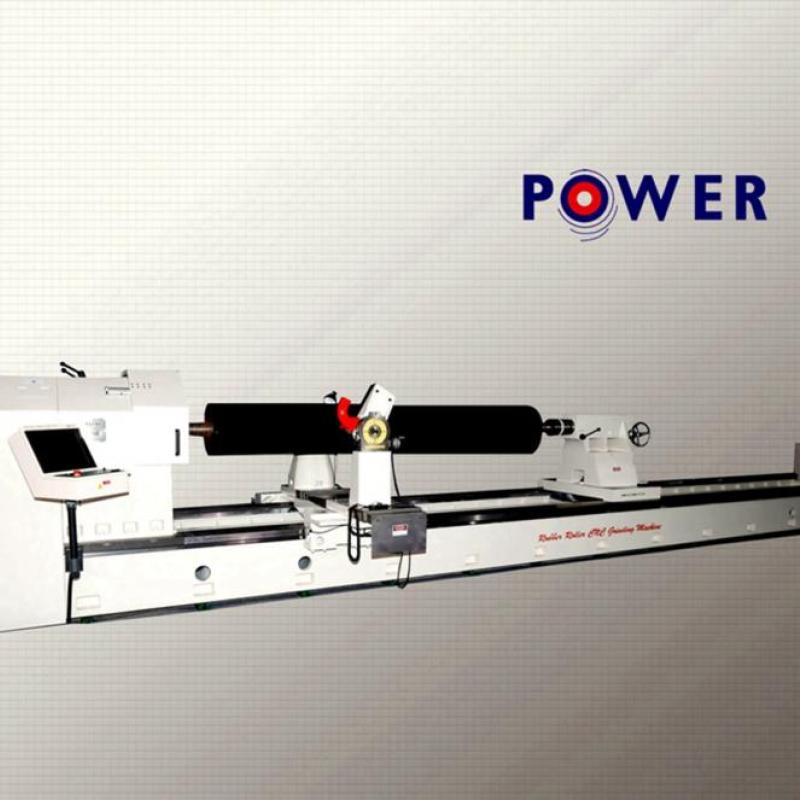

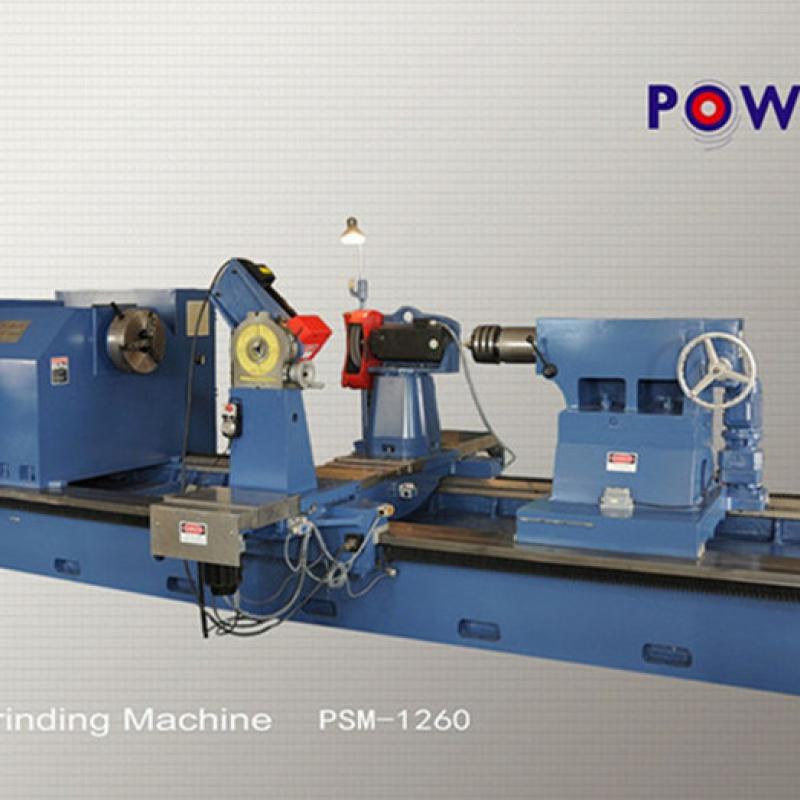

PSM series grinding machine for rubber roller processing is particularly designed and artificial to replace the past roller processing approach with the useful resource of the usage of metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past approach to manufacture roller, which the high-excellent of roller is difficult to acquire the requirement of the present standard. The essential motive lies withinside the form of lathe.

Contacta ahora

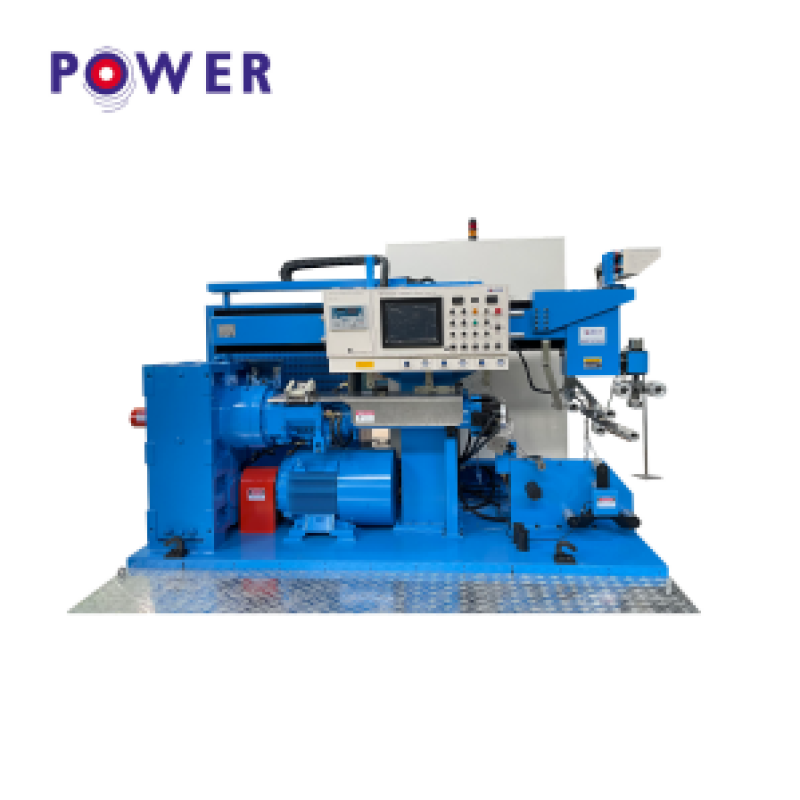

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contacta ahora

Special Hickey-Picker Rubber RollerStrength enterprise adopts numerous special glue inventory made in america and germany to manufacture commercial robber rollers. for printing enterprise, there are alcohol plate moisturizing rubber roller, uv inker, rubber roller transmitting and sparing ink.

Contacta ahora

Product description1. the pcm-8040 model is appropriate for renewing commercial rubber rollers.2. eliminating antique rubber by using special ring cutter.Three. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding system.Four. flawlessly retaining the unique dynamic balance of the roller core.Five. giving more reliable assure for the bonding of the rubber and steel cores.6. saving expenses and labors with this stepped forward manufacturing machine.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachinePCM Multi-Purpose Stripping Machine is specially researched, developed and designed for treating old rubber rollers. PCM Multi-Purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process.

Contacta ahora

Product description1. The PCM-1660 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacta ahora

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacta ahora

Product description1. the pcm-8040 model is suitable for renewing business rubber rollers.2. doing away with old rubber by special ring cutter.3. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding manner.Four. perfectly maintaining the unique dynamic stability of the roller middle.Five. giving extra dependable guarantee for the bonding of the rubber and metal cores.6. saving charges and labors with this progressed manufacturing device.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contacta ahora

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contacta ahora

QUALITY CONTROL Precisely checked with our own made PSF series rubber roller laser measuring instrument. APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.PRODUCTIONBeing extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality

Contacta ahora

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

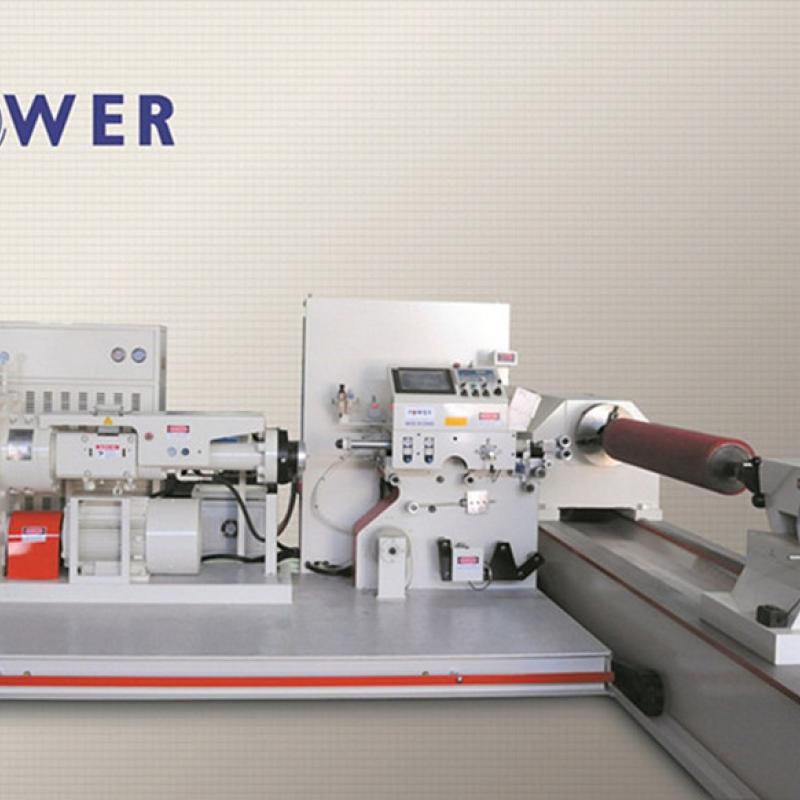

PTM-1510 Industrial Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contacta ahora

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contacta ahora

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacta ahora

Product description1. the pcm-8040 model is suitable for renewing industrial rubber rollers.2. putting off antique rubber by way of special ring cutter.Three. replacing the conventional sand-blasting and solvent washing procedure by advanced belt-grinding process.4. flawlessly keeping the original dynamic balance of the roller middle.5. giving more dependable assure for the bonding of the rubber and metallic cores.6. saving fees and labors with this advanced manufacturing gadget.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacta ahora

The feature of PSM series grinding machine for rubber roller processing1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max. linear speed of grinding head is over 90m/s.

Contacta ahora